Evoloop® 945

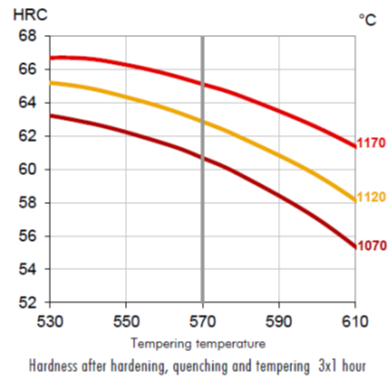

Evoloop® 945 is a high speed steel with a low alloy content compensated by an optimal ratio of carbon-vanadium which gives a very hard martensitic matrix. Hot hardness is improved with 2.5% cobalt. This steel allows for lower austenitizing temperatures to reach the same hardness.

Chemical composition

| C | Cr | Mo | W | Co | V |

|---|---|---|---|---|---|

| 0.91 | 3.7 | 5.0 | 1.8 | 2.5 | 1.2 |

Standards

- Europe : HS 2-5-1-3

- Sweden : SS2737

Properties

Machinability

Wear Resistance

Toughness

Hot hardness

Grindability

Heat treatment

Delivered Hardness

- Soft annealed : 250 HB

- Cold drawn : 275 HB

- Cold rolled : 275 HB

Characteristics

Evoloop® 945 can be worked as follows:

- machining (grinding, turning, milling)

- polishing

- hot forming

- electrical discharge machining

- welding (special procedure including preheating and filler materials of base material composition).

-

-

-

Round bars Ø 0.6 to 410 mm

-

-

Strips (cold rolled) test